This article first appeared in Volume 9, Number 1, of the Datsun Roadster Review magazine.

Rust by Syd ChromeRust, the very word brings shivers to the car owner, let alone the car collector or restorer Unfortunately it is simply nature’s way of undoing what man has done i.e. returning steel to its natural state of iron oxide.

For the car enthusiast it is helpful to understand the causes and the types of corrosion found in vehicles, and then the various ways you can combat them.

Since general corrosion proceeds at roughly the same speed over the entire area exposed to a corrosive medium, it results in fairly even corrosion. Localized attack, the other type of corrosion, proceeds very rapidly in limited portions of the area, often taking the form of concentrated attacks, resulting rather quickly in holes or cracks. The commonest types of localized attack in cars are:

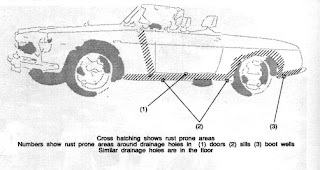

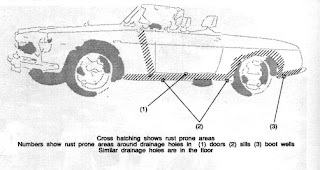

- Crevice corrosion, which occurs in narrow gaps filled with liquid. It is usually caused by sol called “differential aeration cells”. A cell forms because the oxygen in the air has greater difficulty penetrating the gap than it does the rest of the surface. As a result, the steel inside the gap because and anode and corrodes, while the steel at the aperture of the gap becomes a cathode protected against corrosion. Crevice corrosion is often aggravated by moisture remaining longer in the gap than in other areas because drying takes place more slowly. This type of corrosion is found at the rear of the front mudguards, rear wheel arches and door edges in the Sporties.

- Deposit attack, which can occur beneath non-metallic deposits and coatings. It is due to moisture being retained by the deposit so that a differential aeration cell develops in the same way as in crevice corrosion. This type is found in the sills, floors and boot floor, due to the ingress of both water and dirt (hence, mud).

- Corrosion fatigue, which is damage inflicted on the material as a result of varying loads, combined with the influence of a corrosive medium. It can result in cracks. This is found in the boot floor of the Sports due to the weight of the fuel tank.

- Pitting, which covers small areas, but can often attain considerable depths. This typically occurs on the rear bumper bar around the exhaust pipe area due to the chemicals from the exhaust fumes.

- Galvanic corrosion, which occurs when two different metals are combined to form a galvanic cell. Usually the metals are steel or cast iron combined with copper or aluminum. Hence we have the corrosion of the alloy head if corrosion inhibitor is not used in the cooling system.

OK, I hear you say, enough of this technical rubbish, what can we do about it? Well, the foolproof way to prevent your car from rusting is to make sure it never gets wet – no water, no galvanic cell; this, however, is not a very practical solution. Unfortunately though, water is the problem; or, more correctly, the mud it creates. This gives you the first practical thing you can do – GET RID OF CHUNKS OF DIRT.

When was the last time you thoroughly cleaned the inside of the front mudguards? To do this easily you will need to remove the wheel so that you can get the hose to fire it into the rear inside of the headlight area. Also get your head into the various surfaces that collect dirt, as it may also be necessary to reach in with you hand to loosen any clumps that the hose can’t shift (there is one drawback however – you might find/create some hole that you didn’t have as the steel is no longer there because it has totally rusted away).

The same can be done, although less vigorously, inside the boot wells and rear wheel arches. The water and dirt should drain away via the drain holes, or you can discretely make your own. The floors and the boot floor can also be cleaned by hand to remove any dirt. And don’t forget to check that the drain holes in the bottom of the doors and the sills are clear of any obstructions. There is also a drain hole in the bottom of the High Screen’s “A” pillar; this can be seen if you open up the door and look at the area on the body opposite the top hinge.

It is imperative though, that you try to prevent the entry of water into the vehicle. Try to identify accurately where the water is getting in and take steps to stop it. There are very good products, such as the silicone sealers in various colours, which can be used to seal up holes or cracks. This even applies to the soft top where you can smear along the inside of the seams to prevent water entry. If it is not possible to prevent the water from getting in, make sure it can get out quickly, and dry it out as soon as possible.

It is also possible to stop the rust getting any worse by sealing it off from the atmosphere. Do this by using one of the products on the market; even the old fish oil is effective at doing this. The only problem with these products is that if you decide to restore the car totally at a later date, they do require a little extra work to remove them. However the other side of the coin is the extra work in repairing the more severely rusted panels.

As far as pitting or corrosion on the chrome work goes there isn’t any easy solution. It can be kept in check by the application of some car polish or wax in order to seal it off from the environment.

The cooling system also tends to neglected by most people. This must be cleaned out by flushing it every twelve months. Again, use one of the readily available products and follow their directions. After the system has been cleaned, it is most important that you add a corrosion inhibitor to the water in order prevent serious and expensive damage to the allow head and water pump. Personally, I don’t believe that a so-called “water pump lubricant” is necessary – it is not possible for any liquid to get to that bearing as it is a sealed unit and the carbon seal doesn’t need lubricating.

What is important though, is that the correct concentration of inhibitor is obtained. A recent test indicated that at concentrations less than 30% the solution was actually more corrosive than plain water. I use a 2.5 litre bottle of inhibitor (96% ethylene glycol) and top up the cooling system with water; this gives a concentration of about 50% and has proved to maintain the system in good order for well over twelve months.

Well, that about covers the major points on vehicle corrosion. Now get out there at the first convenient opportunity and carry out some preventative maintenance – both you and your Sports will better for it.

Note: Many thanks once again to our cobbers in the Datsun Fairlady, Silvia and Sports Owners Club for a very worthwhile article (from the October-November issue of “Dat Chat”). It seems that even Aussie Sporties are prone to the evil cancer that eats our cars. Get in there and clean the little perishers before they are too far gone.

This used early style universal joint on the steering column is used on all Datsun Roadsters from 1962 -1968. All components have been cleaned, painted, and checked for wear and ready to install.

This used early style universal joint on the steering column is used on all Datsun Roadsters from 1962 -1968. All components have been cleaned, painted, and checked for wear and ready to install.